Home

Resources

Resources

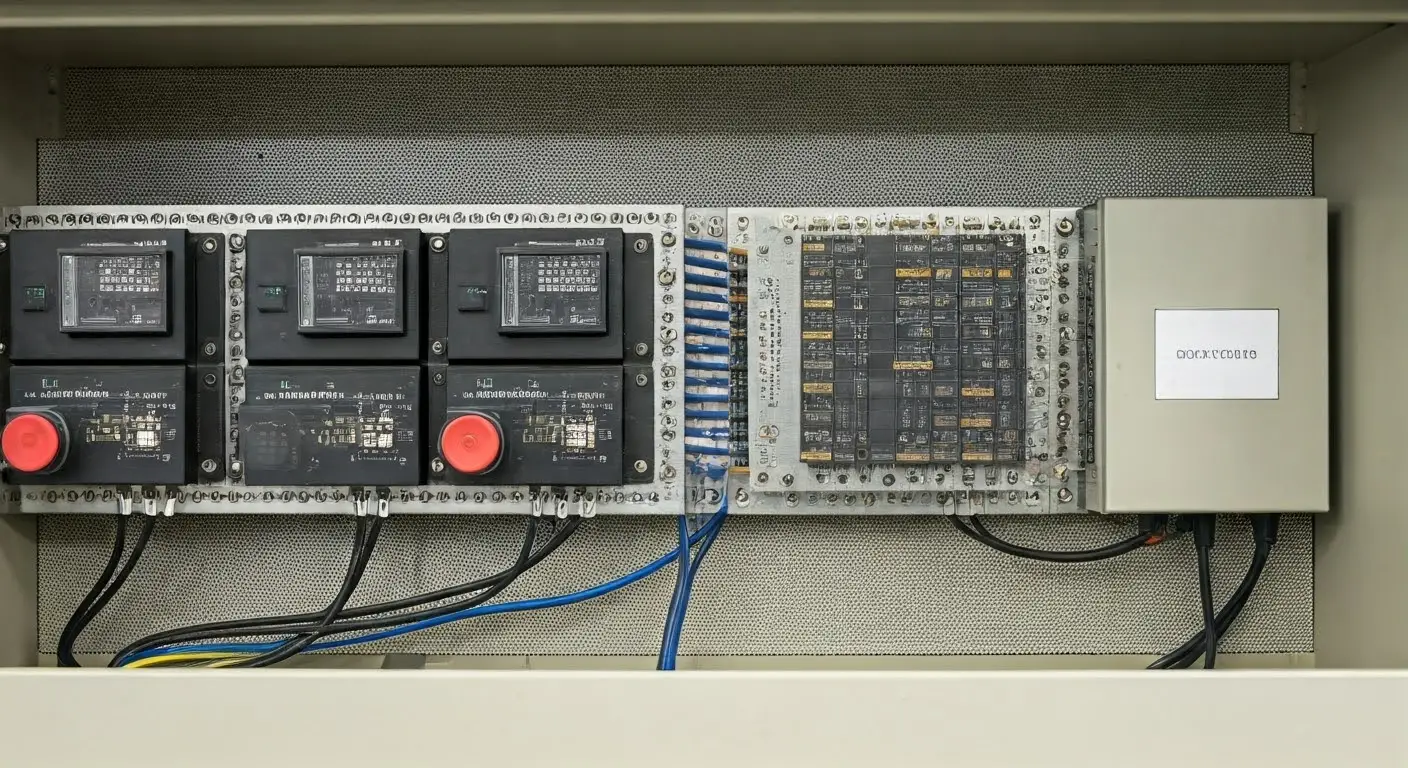

Understanding Electrical Control Panels

Learn the fundamentals of electrical control panels and their applications.

Electrical control panels are essential components in industrial and commercial electrical systems. They house various electrical devices such as relays, switches, and circuit breakers, controlling power distribution and ensuring safety. Control panels can be customized to meet the specific needs of various applications, including motor control, automation, and power management. Understanding the different types of control panels—such as MCC, PCC, and PLC panels—can help in selecting the right solution for your project. Effective design and manufacturing practices ensure reliability and efficiency, crucial for maintaining operational excellence in any facility.

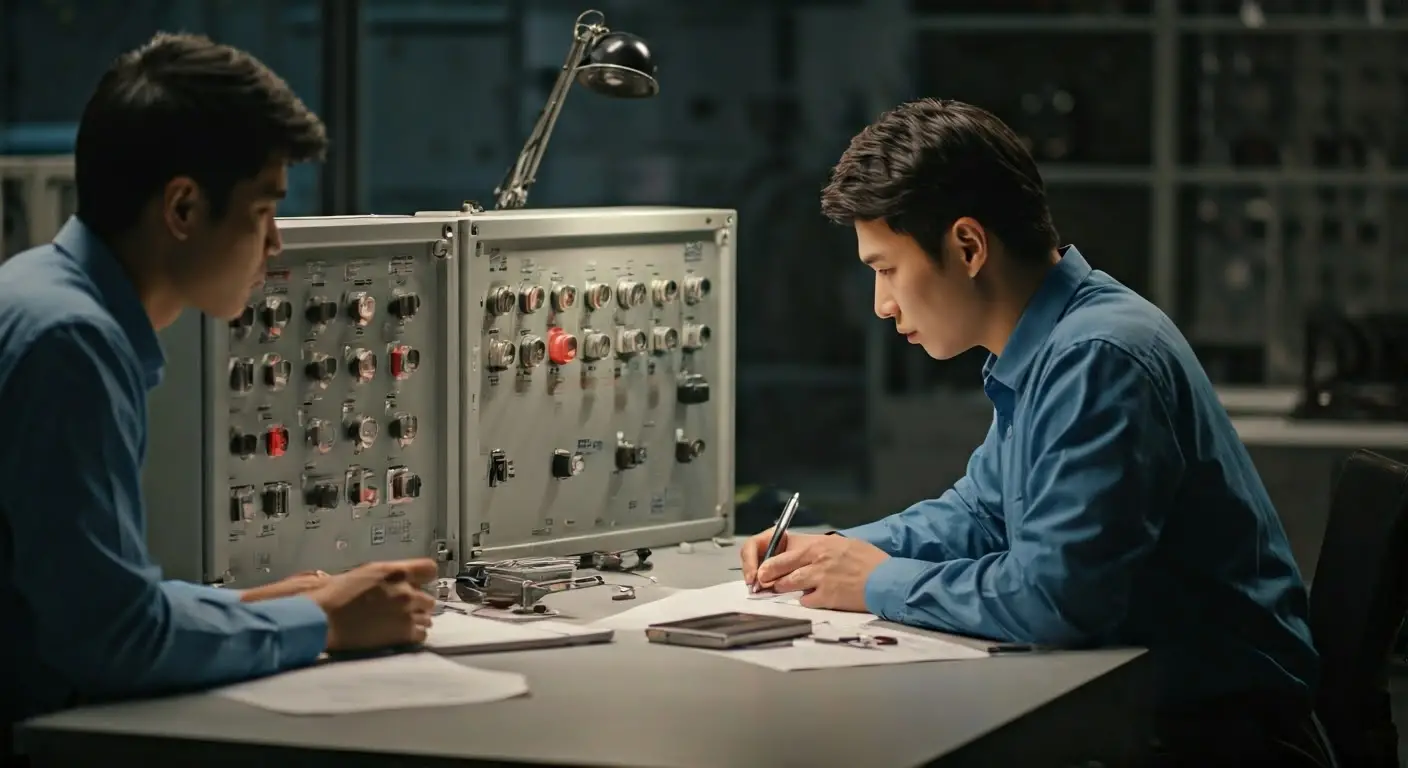

Customizing Control Panels for Your Needs

Explore how customized control panels can enhance efficiency.

Custom control panels are designed to meet specific operational requirements and industry standards. By analyzing the unique needs of your business, manufacturers can create panels that optimize performance and integrate seamlessly with existing systems. Customizations may include specialized components, unique layouts, and enhanced safety features. The benefits of tailored solutions include improved efficiency, reduced downtime, and better compliance with industry regulations. Engaging with experienced engineers during the design phase is crucial to ensure that all technical specifications are met and that the end product aligns with your operational goals.

The Importance of Regular Panel Maintenance

Discover why maintenance is crucial for electrical panels.

Regular maintenance of electrical control panels is essential to ensure their longevity and performance. Routine inspections can help identify potential issues before they lead to costly failures. Maintenance tasks include checking connections, cleaning components, and testing functionality. Additionally, adherence to maintenance schedules can help comply with safety regulations and reduce the risk of electrical hazards. By investing in regular upkeep, businesses can enhance operational reliability, minimize downtime, and extend the lifespan of their control panels, ultimately saving on replacement costs and improving overall efficiency.

Safety Standards in Electrical Panel Manufacturing

Learn about essential safety standards for manufacturing panels.

Adhering to safety standards in electrical panel manufacturing is critical to ensuring the safety and reliability of electrical systems. Standards such as ISO 9001:2015 guide manufacturers in maintaining quality management systems. Compliance with local and international safety regulations ensures that panels are safe for operation and minimizes the risk of accidents. Key aspects include proper labeling, ensuring grounding, and using quality materials that withstand operational demands. By prioritizing safety in manufacturing processes, companies can protect their workers, clients, and property from electrical hazards, fostering a culture of safety and reliability.

Frequently Asked Questions

Get Your Custom Quote

Fill out the form to receive a tailored quote for your electrical panel needs. We prioritize your requirements.

NEXA CONTROLS

9:00 AM to 6:00 PM Mon to Saturday

Copyright © Nexa Controls 2025